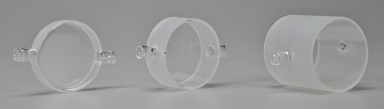

HunterLab D04-1015-423 flow cell with 7 mm ID/9 mm OD inlet ports, centered in D02-1009-960 Flow Through Cell Holder

A flow through cell can be a handy solution for continuous sampling and ease of measurement with a transparent, liquid product.

HunterLab offers both manual loading and flow transmission cells in a range of path lengths.

| HunterLab Product Number | Path Length (mm) | Diameter of Measurement Face (mm) | Port OD/ID(mm) | Approximate Cell Volume Needed (mL) |

| D04-1015-323 | 2 | 51 | 7/9 | 15 |

| D04-1015-179(manual loading – no pump needed) | 2 | 51 | 7/9 | 15 |

| C04-1001-958 | 10 | 51 | 7/9 | 20 |

| C04-1001-959 | 20 | 51 | 7/9 | 35 |

| CMR-2311 | 33 | 51 | 7/9 | 65 |

| C04-1001-960 | 50 | 51 | 7/9 | 90 |

All flow cells will fit in the transmission compartment of HunterLab sphere instruments using a D02-1009-960 Flow Through Cell Holder. We also have a version of this holder with a containment spill tray.

The inlet and outlet ports are 7-mm ID and 9-mm OD to permit a high flow rate and allow the same tubing and pump to be used for all cell path lengths.

The flow cell is aligned in the holder with the inlet and outlet ports aligned vertically such that the transparent liquid will feed from the bottom to minimize air bubbles.

The construction of the cells is clear annealed borosilicate, which can be heated in a water bath up to 100 degrees Centigrade without difficulty.

Flow Cell Operation

- Two lengths of tubing are attached to the 9-mm OD of the cell port. At each end of the tubing, it is good idea to attach a piece of glass tubing or a dispensing wand to be lowered into a beaker of liquid sample.

- Fit the D02-1009-960 Flow Through Cell Holder in the transmission compartment against the TTRAN (sphere side) port of the HunterLab sphere instrument.

- Place the flow cell in the holder using the spring-loaded guide to center it flush at the port. The cell is oriented in with the outlet port at the top.

- Loop the bottom length of tubing through the pump head.

- Lower both tubing ends into a beaker filled with distilled water.

- Turn the peristaltic pump on. The pump rubs on the outside of the tubing creating an internal vacuum within the tubing that pulls liquid into the cell. Air is automatically forced out of the flow cell through the top outlet port while liquid sample is drawn into the bottom port.

- The following is an optional but recommended PQ Performance Qualification step. As soon as the flow cycle is complete, take a measurement of the flow cell + DI water in EasyMatch QC. The color values should be L* = 100.0, a* = 0.0, b* = 0.0, Yellowness Index YI = 0. APHA/Pt-Co = 0, closely. If this is the case, the operator is performance-qualified to continue liquid sample measurements.

- Turn off the pump and drain the DI water from the flow cell and place inlet/out tubing into a beaker of liquid sample and make a measurement after the flow cycle is complete. One reading is usually sufficient for a transparent liquid. An averaged timed measurement of 2 or 3 readings is optimal to obtain repeatable measurements.

- To flush the system, turn off the pump and drain the liquid sample.

- Place the glass ends of the tubing into a beaker of water/solvent and cycle using the pump until clean.

Source: Peristaltic Pump and Tubing

For all path lengths, HunterLab flow transmission cells have inlet and outlet ports that are 7 mm ID and 9 mm OD. To keep costs low for this flow cell, the user can purchase any pumping system, direct drive or peristaltic (preferred) that will attach to those port dimensions.

Given the small volumes needed to fill these flow cells, a variable rate peristaltic pump has been found to work best. There are three components to a peristaltic pump system – a variable speed drive, pump head and tubing. While other suppliers are acceptable, MasterFlex pumps and tubing from Cole-Parmer have been found to work well and are available world-wide.

- MasterFlex L/S TW 07554-80 Controller Drive for 120V; TW 07585 for Controller Drive 230V has a variable rpm from 7 to 200. The 120V version will handle voltages from 90 volts to 130 volts, 50 or 60 Hz. The 220V version will handle voltages from 180 volts to 260 volts, 50 or 60 Hz.

- MasterFlex L/S Easy-Load 3 Pump Head 3 SS will accept tubing diameters appropriate for a 9 mm OD cell port and provide variable flow rates from 27 to 770 ml/minute.

- Tygon tubing is clear, quite robust, economical and has good product life as peristaltic tubing. It has an operational temperature range of -50 to 74 degrees C. MasterFlex 06509-18 Tygon LS/18 tubing (PVC-based) or HV-96419-18 Puri-Flex LS/18 tubing should provide a snug fit on the 9 mm OD cell port. If a higher sample operating temperature is required, other types of tubing can be used.

- MasterFlex 30619-09 size 36 Stainless Steel Dispensing Wand or less expensive 40610-02 Plastic Straight Connecting Barbed Fitting may be helpful in placing the tubing end into the beaker of liquid sample.