FAQ: “I have worked with a company measuring the color of sports drinks. Now this company is interested in fruit drinks and also in carbonated soft drinks. Have you worked with these types of beverages? Any advice or recommendations?”

Fruit drinks contain:

- water

- corn sweeteners

- may contain some fruit juice or fruit solids

- flavors (oil emulsions)

- may have clouding agent which is usually citric acid. Putting in a clouding agent to create a hazy appearance is a marketing decision which depends on the consumer association with the type of drink.

In a fruit drink, whether there is any natural fruit juice or not, the appearance of haze can be created by the presence of oil flavor emulsions and/or clouding agents such as citric acid. These are added on purpose to create a hazy appearance in some flavors of fruit drinks such as pineapple, lemonade, grapefruit and guava where the consumer expects some scattering.

For other fruit drink flavors such as apple, cream soda or grape the consumer does not have the expectation of a hazy appearance and no additional clouding agents are added.HunterLab can measure both lot-to-lot color and haze (or no haze for clear drinks) inherent in different fruit drinks.

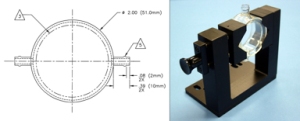

If the beverage is carbonated (a separate source of scattering), it should be decarbonated to remove the carbonation as an unnecessary cause of scattering (independent of color) and measurement variation.To de-carbonate the beverage, place the liquid sample in a sonicator (there are a number available but I have seen a Branson Sonicator in successful use in the lab) that breaks up the carbonization by bombarding with Ultrasound for 60 seconds. Some care has to be taken that the carbonated beverage be placed in a container at least twice the volume of the beverage because when the ultrasound pummels the carbonization, the release of carbon dioxide gas can effervesce suddenly.

Another low-tech option to decarbonization is to place an air hose from the normal lab air supply into the beverage and gently run the air for about 4 minutes. The slow stream of air bubbles break up the carbonization gradually.